iso 8573 7 micro testing of compressed air|iso 8573 compressed air testing : companies ISO 8573-7 dictates that two types of controls exist that “shall be” free from contamination. The first type of control plates is called blinds, these blinds (before and after) are to . See more WEB2 de set. de 2021 · Mais uma vez o canal fapfap games foi deletado e estou aqui novamente, mas com um posicionamento totalmente diferente já que o youtube não quer que eu contin.

{plog:ftitle_list}

WEBFind out who killed Allie, how Tory reacted, and what's next for the characters of "The Watchful Eye" Season 1. Executive producer Emily Fox answers seven burning questions from the thrilling finale of the Freeform .

Compressed air is an often underestimated but crucial utility, the quality of which must be monitored periodically to fulfill national and international standards. The International Organization for Standardization (ISO) publishes world-class standards for products, services and systems, to ensure quality, safety and . See more

Analyzing micro burden data at point of use outlets throughout compressed air pipeline systems at a given time, acts as a window of observation into the control of the facility. Maintaining control means proper preventative maintenance, microbial monitoring . See moreISO 8573-7 dictates that two types of controls exist that “shall be” free from contamination. The first type of control plates is called blinds, these blinds (before and after) are to . See moreAseptic technique is a term that refers to movements, actions, attire and attitude when working in a scientific or environmental sampling capacity. Testing compressed air may not seem like the proverbial environmental sample, but it is. Taking a small . See moreMost impact air samplers are made to use a sterile tube to sample the outlet air into the inlet port of the unit for analysis. For simplicity reasons . See more

Micro Testing of Compressed Air or Bioburden Testing per ISO 8573-7 is generally conducted by the pharmaceutical, medical device and food industries. Microbial contaminants found in .Micro [BS ISO 8573-7_2003] -- Compressed air. Test method for viable microbiological contaminant content - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Compressed air. Test

The Safe Quality Food Institute (SQFI) has introduced a new Safe Quality Food Manual (ISO 22000) in the U.S. According to the standard, food processors must test annually for factors including particulate, water, oil, .This part of ISO 8573 specifies a test method for distinguishing viable, colony-forming, microbiological organisms (e.g. yeast, bacteria, endotoxins) from other solid particles which may be present in compressed air. One of a series of standards aimed at harmonizing air contamination measurements, it provides a means of sampling, incubating and determining .

ISO 8573-7 Micro Testing of Compressed Air. ISO 8573 Sampling & Testing Methods. Previous Lesson. Back to AirCheck Academy. Next Lesson. Amanda Richards 2021-11-30T11:59:31-06:00. Share This Article. Facebook Twitter .

Compressed air — Part 7: Test method for viable microbiological contaminant content. . ISO 8573-7:2003 specifies a test method for distinguishing viable, colony-forming, microbiological organisms (e.g. yeast, bacteria, endotoxins) from other solid particles which may be present in compressed air. One of a series of standards aimed at .We offer ISO 8573-1 and ISO 8573-7 compressed air testing options. . Micro Bacteria, Yeast, Mold. Microbial Testing. Bacteria, yeast, and mold are all particularly dangerous to end products and can result in recalls and loss of production time. .ISO 7183, Compressed-air dryers — Specification and testing; ISO 8573-2, Compressed air — Part 2: Test methods for oil aerosol content; ISO 8573-3, Compressed air — Part 3: Test methods for measurement of humidity; ISO 8573-4, Compressed air — Part 4: Test methods for solid particle content; ISO 8573-5, Compressed air — Part 5: Test methods for oil vapour and .

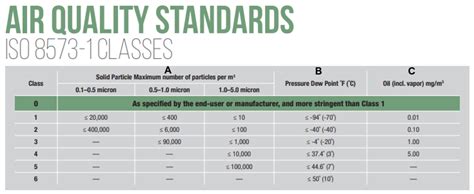

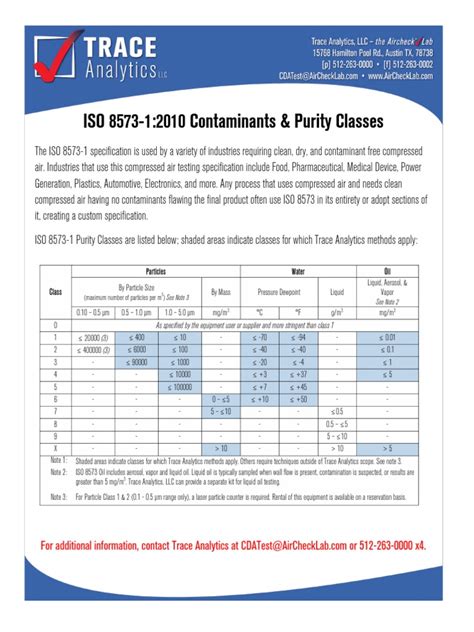

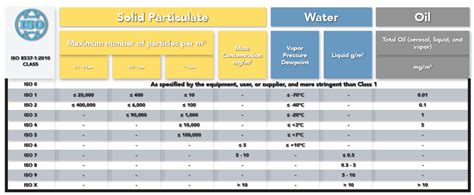

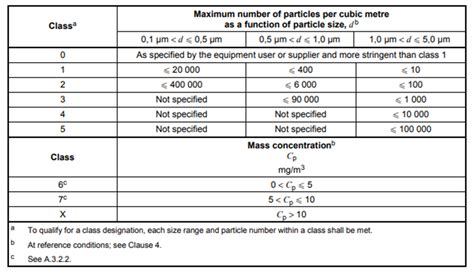

Here too, continuous Measuring ensures that an Alarm can be triggered immediately if the compressed air dryer fails. The sensor enables permanent monitoring of the Compressed air dryer. ISO 8573-4 deals with test methods for the solid particle content. The following table was taken from the ISO 8573-4 standard document:Compressed air testing is performed for establishing a baseline, determining a Purity Class, SQF certification, meet equipment requirements, or commissioning / validation of process air systems using ISO 8573 Particles (P), Water (W), Oil (O), and/or Microbial test methods. . ISO 8573-7 Micro / Microbial Testing is performed in accordance . Here is a guide on using ISO 8573-1:2010 to achieve the proper air quality. Need to understand iso classes for compressed air quality? The right compressed air purity is key to safeguarding production integrity and efficiency.micro-organisms in a compressed air stream. Drying compressed air to a pressure dew point (PDP) of -40°F/°C (ISO 8573-1 Class 2) removes moisture that micro-organisms need to thrive. How important is the quality of the air piping system in reducing micro-organisms?

Compressed air and gases are commonly referred to as a manufacturing facility’s Fourth Utility driving the food and beverage industry, but is often overlooke. Therefore, it’s in all our best interests for food processors to select the proper compressed air equipment. The ISO 8573 air quality standards and ISO 12500 compressed air filter standards make the basis for air treatment product selection much easier. SPX FLOW’s Hankison Filter is Designed to Meet ISO 8573.1 and ISO 12500 StandardsISO 8573-4,Compressed air — Part 4: Test methods for solid particle content . ISO 8573-5, Compressed air — Part 5: Determination of oil vapour and organic solvent content. 3 Terms and definitions For the purposes of this part of ISO 8573, the terms and definitions given in ISO 7183 and the following apply. 3.1ISO 8573-1 and the Compressed Air User Th e ISO 8573-1 standard allows users to select a ‘classifi cation’ for particulate, water and oil, with each classifi cation having defi ned limits of contamination, except for class 0 which is user or equipment supplier defi nable (Class 0 must be more stringent than class 1

ISO 8573-7:2003 Compressed air - Part 7: Test method for viable microbiological contaminant content. ISO 8573-7:2003 specifies a test method for distinguishing viable, colony-forming, microbiological organisms (e.g. yeast, bacteria, endotoxins) from other solid particles which may be present in compressed air. One of a series of standards aimed .ISO 8573-2,Compressedairfor generaluse - Part2: Testmethods for aerosoloil content. ISO 8573-3,Compressedair- Part 3: Test methods for measurementofhumidity. ISO 8573-4,Compressed air - Part 4: Testmethods for solidparticle content. ISO 8573-5, Compressed air - Part 5:Determination of oil vapour and organic solvent content. 3 Terms and definitions

According to the Compressed Air and Gas Institute (CAGI) and the International Organization for Standardization (ISO), the three major contaminants in compressed air are solid particles, water, and oil. CAGI promotes proper use of air compressors with various educational tools, while ISO 8573 is directed at the very specific areas of compressed air purity and test . Compressed air and gases are commonly referred to as a manufacturing facility’s Fourth Utility driving the food and beverage industry, but is often overlooked as a source of contamination. International Organization for Standards 8573 (ISO 8573) provides specifications and contaminant categories for compressed air systems, with part 7 focusing on microbial .Compressed air — Part 2: Test methods for oil aerosol content 1 Scope This part of ISO 8573 specifies test methods for the sampling and quantitative analysis of oil aerosols and liquid oil that can typically be present in compressed air. Test methods for oil vapour are excluded from this part of ISO 8573 as they are covered by ISO 8573-5.Micro-aerosolized droplets are how many members of the microbial world become cross-contaminants via the air mode of transmission. . and procedures. ISO 8573-7:2003, can be utilized across all industries’ compressed air microbial monitoring plans. . while ISO 8573 is directed at the very specific areas of compressed air purity and test .

Agar plate with micro-biological growth from compressed air sample ISO8573-7 is the international standard used to test compressed air for micro-organisms. It is used in conjunction with ISO 8573-4 (solid particulate). Air is ˚rst tested in accordance with ISO 8573-4 for solid particles. Next samples are taken using

iso air quality chart

In addition, ISO 8573-1 Compressed Air : 2010 also identifies microbiological contaminants. The ISO 8573-1 Compressed Air purity classes can be used to describe the quality of a compressed air system or to specify the required quality for a precise application. Compressed air specifications should meet product performance requirements.The International Organization for Standardization (ISO) is the world’s largest developer of voluntary International Standards. It is a network of national standards bodies. These national standards bodies make up the ISO membership. It is an independent, non-governmental organization made up of members from 164 countries. The ISO 8573-1 specification is used by .

ISO8573 - the compressed air quality standard ISO8573 is the group of international standards relating to the quality (or purity) of compressed air. The standard consists of nine separate parts, with part 1 specifying the quality requirements of the compressed air and parts 2 – 9 specifying the methods of testing for a range of contaminants.This part of ISO 8573 specifies a test method for distinguishing viable, colony-forming, microbiological organisms (e.g. yeast, bacteria, endotoxins) from other solid particles which may be present in compressed air. One of a series of standards aimed at harmonizing air contamination measurements, it provides a means of sampling, incubating and determining .

perkin elmer polarimeter calibration

webSee all reviews. Um dos personagens mais interessantes e conflitantes do Universo de Personagens da Marvel da Sony Pictures chega às telas grandes quando o vencedor do Oscar® Jared Leto se.

iso 8573 7 micro testing of compressed air|iso 8573 compressed air testing